Services

Precision Design & Engineering

At Form Tech Mold & Engineering we specialize in both plastic and silicone engineering. We provide our customers with a dedicated service from mold tool design and DFM to mold production and parts manufacturing. With our extensive range of high-end machinery, experienced toolmakers, and customer-focussed approach, we're equipped to tackle even your toughest challenges.

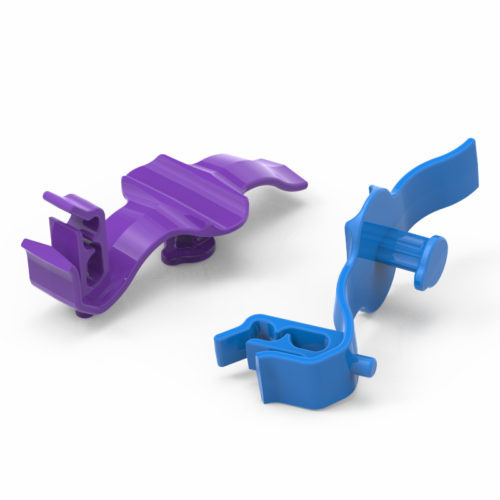

Design & Design for Manufacturing (DFM)

Design is one of our key strengths. The success of any project hinges on the design process. Our design experts are involved from the project’s inception, utilizing Mastercam and Solidworks to ensure success, even with the most complex molds.. We tailor solutions depending on different variables such as material selection, quantities, and tolerances. Our expertise lies in debugging designs to find the optimal solution, leveraging DFM (Design for Manufacture) to ensure repeatability and dependability.

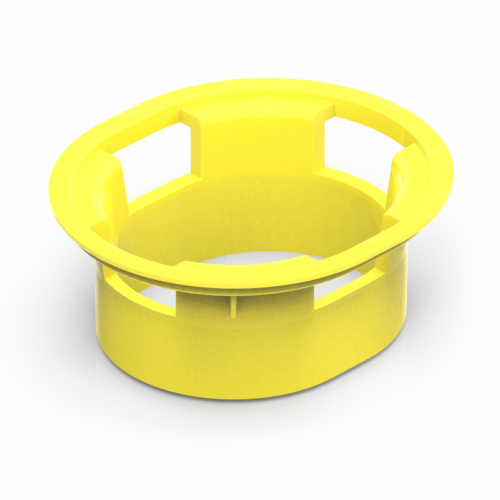

Prototyping R&D

A program’s success often requires prototype molds. Prototyping will not challenge and validate a designer’s ideas but provide valuable insight to the mold designer. Our prototype molds are typically completed in 1-4 weeks and are always suitable for short production runs.

We offer pre-production runs on one of our 3 injection molding machines. Customers can benefit from working with their project team, process engineers and mold builders all under one roof.

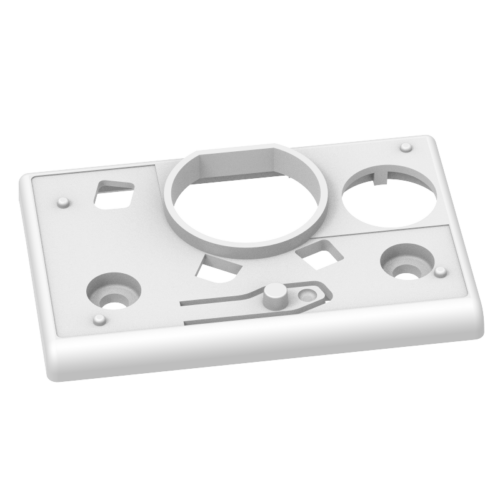

High Precision Production Injection Molds

A program’s success often hinges on the creation of prototype molds. Prototyping not only challenges and validates a designer’s ideas but also provides valuable insights to the mold designer. Our prototype molds are typically completed within 1-4 weeks and are always suitable for short production runs. We offer pre-production runs using one of our three injection molding machines. Customers benefit from having their project team, process engineers, and mold builders all working together under one roof.

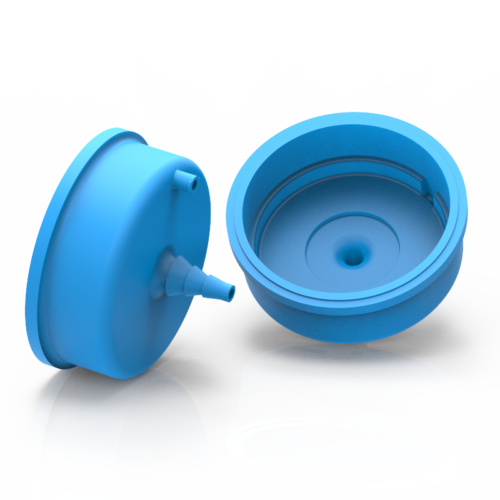

Liquid Silicone Injection Molds

Molds for Liquid Silicone (LSR) are different than molds for thermoplastic. They typically require unique approaches to design and higher tolerances. At Form Tech, we specialize in LSR molds and excel in meeting the specific requirements and precision demanded by this process. We primarily produce silicone molds for the medical and pharmaceutical industry, where precision and quality are paramount. With our extensive experience and focus on meeting the highest standards, we ensure optimal results in every project.

Injection Molding

We have 3 injection molding machines (two thermosplastic and one LSR) on site to carry out testing and debugging of molds. Additionally, we offer molding services for pre-production and production parts.

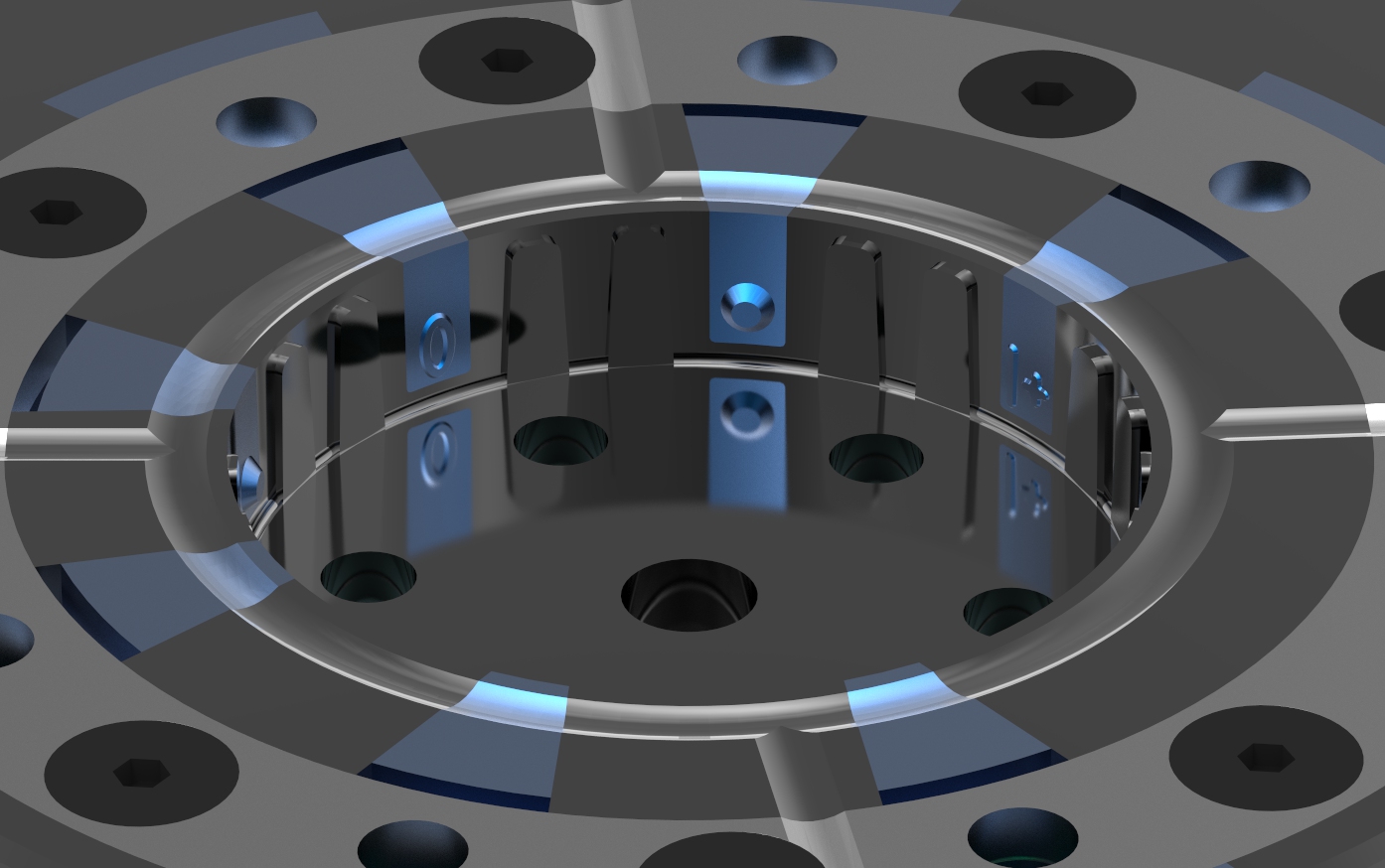

Precision Mold Making

Precision Mold Making ensures your product will perform in the millions of parts and beyond. We invest in the latest technology and inspection equipment to ensure precision to tenths and millionths when needed.